Static Mixer

Working

Laminar Flow

In case of two miscible liquids in laminar flow, the main mechanism in a static mixer is flow division. The elements are helical are arranged in a series of alternating left and right hand 180 twists.

Turbulent Flow

In case of two miscible liquids in a turbulent flow, the main mechanism is radial mixing fluids are constantly moved from the pipe centre to the pipe walls and the fluid change direction with each succeeding element. In case of two immiscible liquids in a turbulent flow, the radial mixing mechanism reduces radial differences in velocity and in droplet sizes.

: SS – 316Material

Viscosity range : less than 1500 cps

Reynolds no. : greater than 500

: ½ “ to 14”Size range

Application : Mixing products into water or water like fluids.

SW-SMx-01 : using for low viscosity. The faster the fluid moves, the faster mixing. Great for mixing products into water or water like fluids.

SW-SMx-02 : using for high viscosity blending application and when

fluid moves more slowly through the mixer

Material: SS – 316

Viscosity range : greater than 1500 cps

Reynolds no. : less than 500

: ½ “ to 14”Size range

Application : Epoxy blending, Fruits into yogurt, Cookies into ice cream, Thermal homogeneity, slurry suspension, Folding/stripping .

Excellent mixing and dispersing even with widely differing fluid

viscosities

Compact designs

Reduced product degradation due to very short residence time

Mixing of sensitive products under minimal shear stress

No deposits and blockages due to excellent cross-mixing

Static mixers deliver a high level of mixing efficiency, formation of byproducts can be dramatically reduced.

Low energy consumption

Installation is very easy

Static Mixers are available in all standard pipe sizes and in the case of open channel designs, are available in any size with no upper limit.

Pulp and Paper Processing

Pharmaceuticals

Oil Refining

Petrochemicals

Food Processing

Natural Gas Processing

Water and Waste Water Treatment

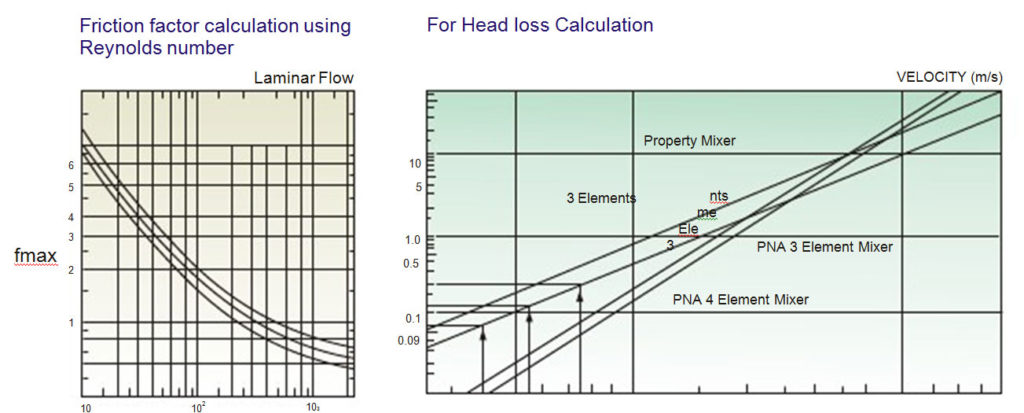

For calculating element following criteria used :

Reynolds no.= Dvñ/µ

Re<10 = 24-36 element

10<Re<100 = 18 element

100<Re<1000 = 12 element

1000<Re<10000 = 6 element

Re>10000 = 4 element

?P =3.061×10 6 f nsmxpx(u)2 xE

G value calculation

G = v(hf gñ/ìt)

Pipe diameter

(D)in meter = v(4Q/pv)