Stripper Column

Stripping columns are used to remove volatiles from water such as volatile hydrocarbons (e.g., benzene, toluene and xylene), volatile chlorinated hydrocarbons , to remove low boils such as methanol, ethanol etc from water

These stripping columns are equipped with either tray or packed column based on the process fluid characteristics and composition

Tray Column:

Tray column are separation devices used in process plants, most often in distillation towers or stripper column. The tray column is one the most widely used types of distillation columns. It is also at times referred to as a plate column. The number of trays and stages in the column is designed for the desired purity and difficulty of the separation process.

A tray column that is facing throughput problems may be de-bottlenecked by replacing a section of trays with packings. This is because: | |

packings provide extra inter-facial area for liquid-vapour contact | |

efficiency of separation is increased for the same column height | |

packed columns are shorter than trayed columns | |

Types of Tray:

Sieve tray

Bubble tray

Moving Valve tray

Fixed Valve tray

MOC:

All SS material

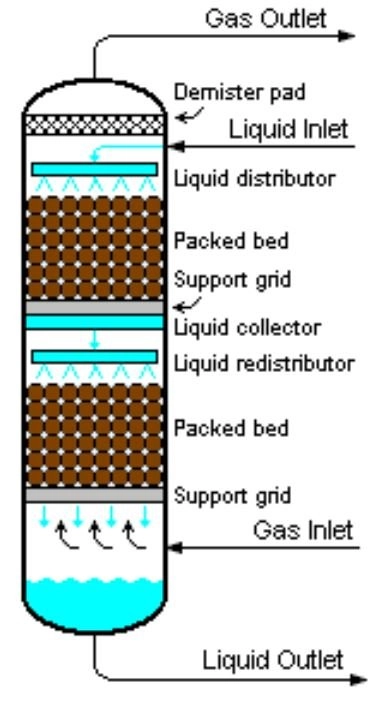

Packed Column:

Demister pad:

Shreewire Mist Eliminator is fabricated in pad form from symmetrical interlocking loops of knitted metal wire or plastic mono-filaments. The pad with a high free volume and large impingement area,can be installed in any existing or new process vessel to provide separation efficiencies upto 99% for particles down to five microns at pressure drops in the vicinity of 25 mm WC. The Shreewire Mist Eliminator is a static, in-line device and in majority of the cases it can be installed in the evaporator, scrubber, pressure vessel etc., without a special housing. There is practically no maintenance required except for cleaning when used in fouling services.

Liquid Distributor:

Liquid distributors are an important component of column internals. They provide adequate distribution of the liquid onto the random packed bed and structured packing. To achieve an intensive mass transfer between the phases, the liquid should be distributed equally across the packed column area. It serves to overcome maldistribution and, poor initial distribution can only be compensated to a limited degree by a larger bed height

Bed limiter:

For metal and plastic random packing, bed limiters are recommended where there is potential for sufficient vapor load to fluidize the top of the bed.

The bed limiter is the most common type. A bed limiter either sits directly on the packing or is attached to the vessel wall. The bed limiter acts as a screen to confine the packing to the defined bed.

Packing:

Random packing uses a random distribution of small packing materials to assist in the separation process.

Random packing is used in separation columns, such as a distillation column or stripping column , to increase surface area for vapor/liquid contact so that chemical separation is more efficient. The small pieces of random packing in a distillation column are designed to form a large surface area where the reactants can interact while minimizing complexity within the column. Random packing is designed to maximize the surface-to-volume ratio and minimize pressure drop.

Structured packing is a type of organized packing used to channel liquid material into a specific shape. It uses discs composed of materials such as metal, plastic or porcelain with their internal structures arranged into different types of honeycombed shapes. These honeycombed shapes are always found within cylindrical columns.

Structured packing cylinders are precisely engineered to provide a large surface area for the liquid to contact without causing resistance that impedes the liquid’s flow.

Support Plate:

Packing support plate, also called packing support grid, is an important tower internals in the packing tower. As its name says, packing support plate is designed for supporting the tower packing bed, including random packing and structured packing. It is also important to load the liquid weight and ensure the normal and smooth mass transfer. The large open area and strict design ensures high efficient gas and liquid distribution and prevent liquid blocking and liquid flooding

MOC:

All SS material and PP